Sep 1, 2022 · Another study reveals that an energy recovery system attached to an aerated static composting pile has an energy capture ranging from 17,700 to 32, 940 kJ/h with a compost vapor temperature range of 51–66 °C (Sokač et al., 2022). Enhancing compost production with energy recovery systems will improve circularity levels of both small- and

Sep 11, 2019 · 5.2 Compost Turning Machine Market Size Forecast By Type 5.2.1 Drum 5.2.2 Elevating Face 5.2.3 Chain Plate 5.3 Market Attractiveness Analysis By Type Chapter 6 Global Compost Turning Machine Market Analysis and Forecast By Power Source 6.1 Introduction 6.1.1 Key Market Trends & Growth Opportunities By Power Source

May 4, 2024 · Updated on May 4, 2024. Turning compost is essential to creating aerobic composting conditions and maintaining a healthy compost pile. However, straining your back while turning your compost material with a pitchfork or shovel to allow airflow is no fun! The best tool for turning compost will make your job easier and prepare quality compost.

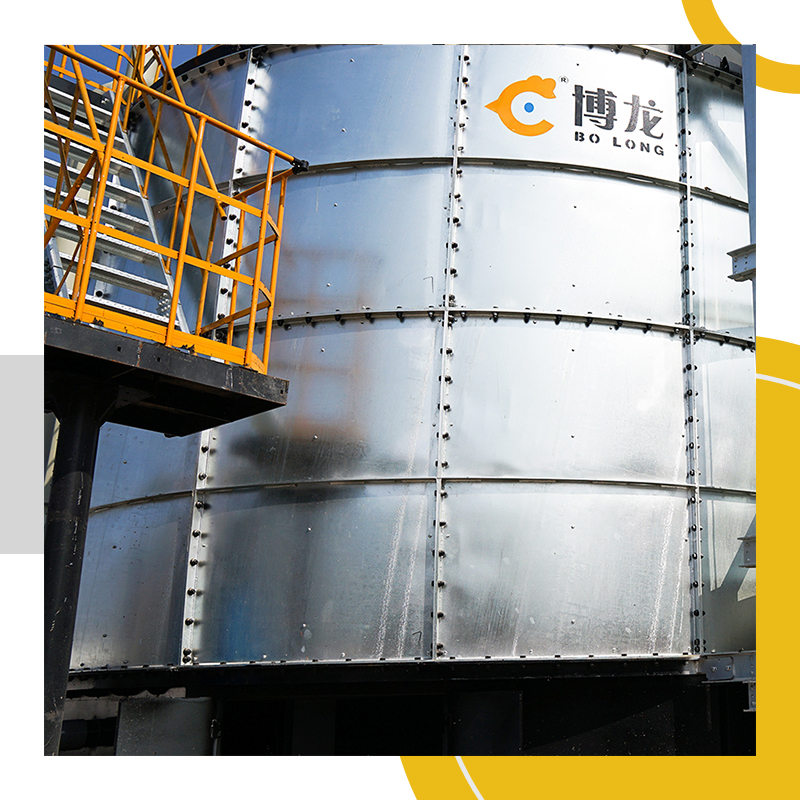

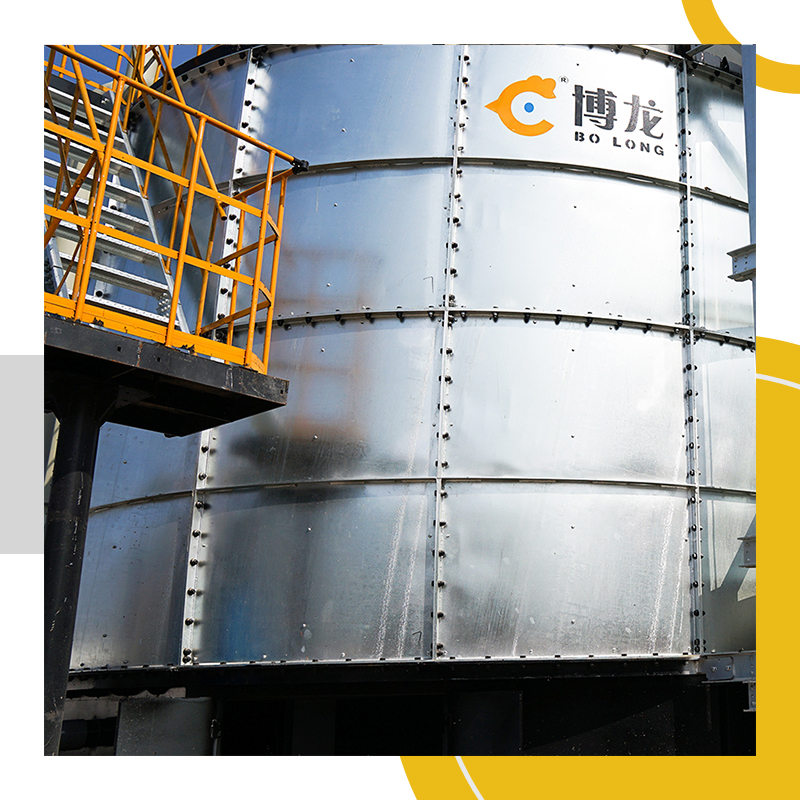

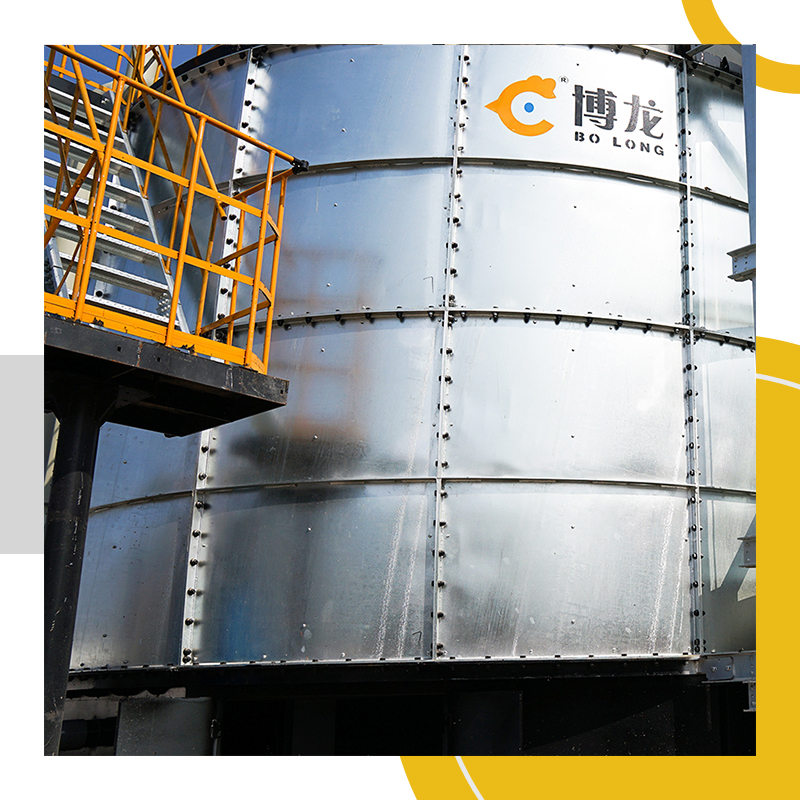

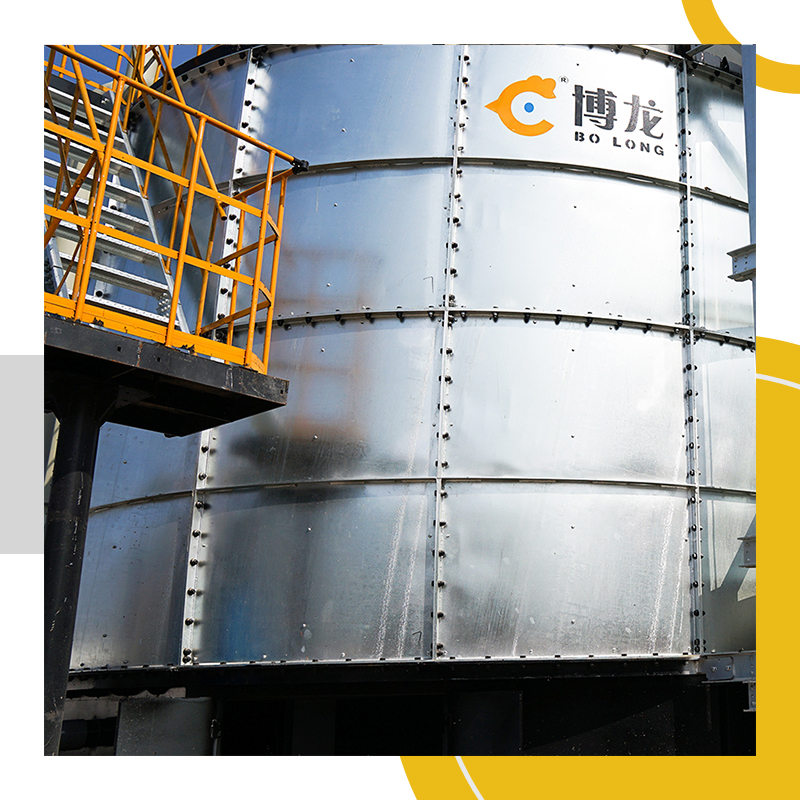

Associated with modern compost technology, this self-propelled compost turning equipment can turn agricultural wastes, livestock manures and organic wastes into ideal and qualified organic fertilizers. It is a cost-effective and energy saving fertilizer facility. Adopted with compact structural design technology, it can turn 400 to 600 cubic

This is also the most energy-efficient mode, using only 0.6 kWh per cycle. Lomi Approved: This is the second shortest mode with a 5-8 hour cycle length. This is the mode you'll choose if you want to compost Lomi approved bioplastics. Grow: This is Lomi's longest mode with a 16-20 hour cycle length. Although it takes the longest, this is the

Dec 18, 2023 · Composting is a controlled, aerobic (oxygen-required) process that converts organic materials into a nutrient-rich, biologically-stable soil amendment or mulch through natural decomposition. The end product is compost. Microorganisms feed on the materials added to the compost pile during the composting process.

Nov 28, 2023 · 4. Energy-Efficient Operations. Energy efficiency is a top priority, and modern Waste Compost Machines are designed with this in mind. Embracing Energy Efficiency: Low Power Consumption: These machines are engineered to consume minimal energy while delivering maximum output, thereby reducing their overall carbon footprint.

A new way to turn food waste into energy. Researchers have been working for years to develop to turn food waste into a viable and economic energy source. Now, researchers at Cornell University have found a new way to capture nearly all of the energy in a food waste product, leaving little behind to fill a landfill. First, the

Hence, our composting turners could meet all requirements of different organic fertilizer production lines. Compost Making Machine. Compost Making Machine. Model: SX-300. Color: Yellow (can be customized) Size: 4930×1620×2660mm. Application: Turning organic wastes piles. Feature: Also can be used as a forklift.

Jun 8, 2020 · Advantages of Wheel-type Compost Turner. * High turning depth: as deep as 1.5-3m, better fermenting effect. * Large turning span: as wide as 30m, efficiently reduce the wall construction of fermentation tank. * Low energy consumption: adopt unique energy-efficient transmission mechanism, energy consumption is decreased by 70% compared with

It installs two rail on the two sides of the groove to move large scale groove compost turner. Before composting, you should put manure or piles into the groove. The double paddle groove type mixer produced by our company has 3 national patents. The span can be between 3 and 30 meters and the height can be 0.8-1.8 meters.