Efficient commercial composting equipment designed for high-temperature, high-humidity, and water-scarce regions. Reduce odor, prevent leachate, and produce organic fertilizer in 7 days.

For years, a major Vietnamese swine farm grappled with mounting manure accumulation—a problem that not only jeopardized animal health but also triggered environmental pollution and administrative penalties. Amid tightening environmental regulations and mounting societal pressure, the farm urgently required an efficient and eco-friendly solution.

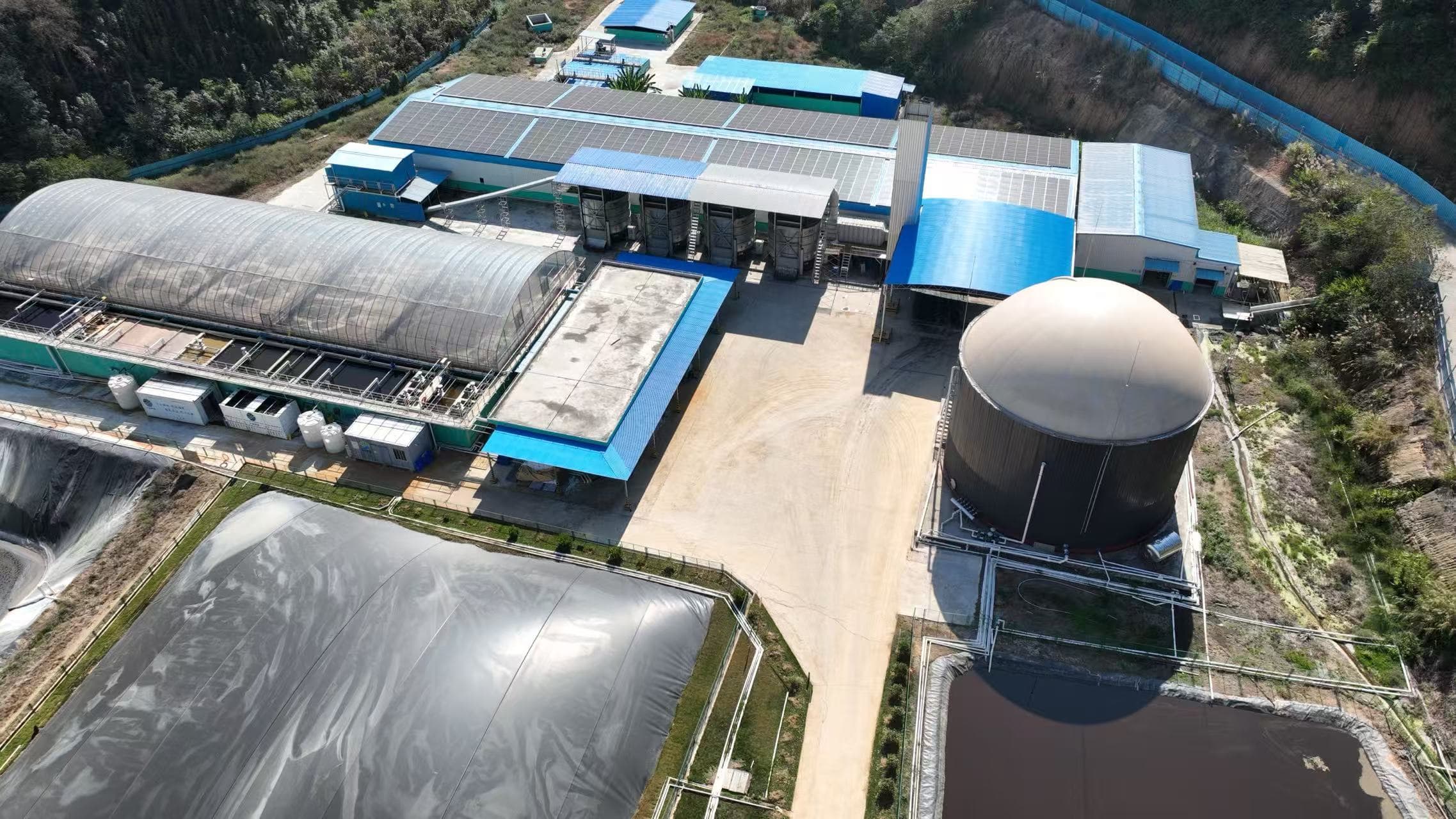

At this critical juncture, Bolong—a leading enterprise specializing in livestock manure management—provided a comprehensive one-stop solution. Leveraging its proprietary high-temperature aerobic fermentation tank as a core product feature, Bolong delivered a holistic manure treatment system.

This article details how Bolong’s technical expertise and innovative approach enabled the farm to achieve a transformative shift toward “harmless and resourceful” manure management.

Large-scale pig farms generate massive amounts of manure waste. Traditional treatment methods often rely on simple stockpiling or discharge, which not only fails to meet environmental standards but may also cause economic losses.

Addressing this industry challenge, Bolong proposed an integrated solution: “solid-liquid separation → fermentation → multi-stage sedimentation → biogas utilization.” This approach achieves green recycling of manure waste while meeting goals of waste reduction, resource recovery, and harmless disposal.

Bolong’s manure treatment solution prioritizes both scientific rigor and practicality. The entire process comprises three key interconnected steps, ensuring thorough, environmentally sound, and efficient manure treatment.

Manure from the pig farm first enters a high-efficiency solid-liquid separator. This step acts as a “pre-processing” stage, separating solids from liquids within the manure.

The separated solids (manure residue) are directly fed into the Bolong pig manure compost tank for rapid biological fermentation in a sealed environment. The separated liquids (manure water) are diverted to oxidation ponds for further purification.

Within the oxidation ponds, Bolong employs a combined approach of multi-stage sedimentation, flocculation, and aeration to thoroughly remove impurities, suspended solids, and ammonia nitrogen from the effluent.

This process significantly improves water quality. Simultaneously, the settled sludge is not wasted but proportionally recirculated back into the compost tank to continue participating in organic fertilizer fermentation, achieving resource recycling.

The fermentation and sedimentation processes generate waste gases. The Bolong solution incorporates biogas collection and purification equipment to extract methane. After purification, this methane can be reused as fuel or energy. Excess biogas is safely flared via a small flare system, ensuring compliant emissions and environmental protection.

This achieves triple harmless treatment of solid, liquid, and gaseous waste, enabling the entire system to realize sustainable utilization from “manure → energy → organic fertilizer.”

Within the entire manure treatment system, Bolong high-temperature aerobic fermentation tank serves as the key equipment for solid waste resource conversion. After solid-liquid separation, the resulting manure residue enters the compost tank directly for biological processing.

Utilizing high-temperature aerobic fermentation technology within a fully enclosed, automatically temperature- and humidity-controlled environment, the tank converts pig manure and other organic waste into high-quality organic fertilizer in just 7 days. The entire process is highly efficient, clean, and free from secondary pollution.

The integrated deodorization system effectively removes odorous gases like ammonia and hydrogen sulfide, maintaining a fresh on-site environment. Simultaneously, the built-in heat exchange system fully recovers thermal energy generated during fermentation, achieving energy savings and reducing consumption, making the entire process more environmentally friendly and

economical.

The resulting organic fertilizer is rich in nutrients like nitrogen, phosphorus, and potassium, offering long-lasting fertility. This fertilizer holds significant economic value in the Vietnamese market, aligning with local green agriculture policies while delivering substantial revenue growth and long-term economic benefits for the farm.

For this large Vietnamese pig farm’s manure treatment challenges, Bolong’s one-stop solution delivered satisfactory results. Powered by its core product—the high-temperature aerobic fermentation tank—Bolong successfully achieved comprehensive management of manure through “reduction, harmless treatment, and resource utilization” using technological innovation.

Choosing Bolong means choosing a cleaner, more efficient, and economically valuable future.

Efficient commercial composting equipment designed for high-temperature, high-humidity, and water-scarce regions. Reduce odor, prevent leachate, and produce organic fertilizer in 7 days.

Bolong’s high-temperature aerobic fermentation tank converts manure to organic fertilizer in 7 days. A closed-loop, eco-friendly solution for large farms in the Middle East. Achieve compliance & boost profit.

Discover how Bolong’s automatic egg collector reduces broken/dirty eggs, improves hatchability, supports animal welfare, and boosts efficiency for African poultry farms.